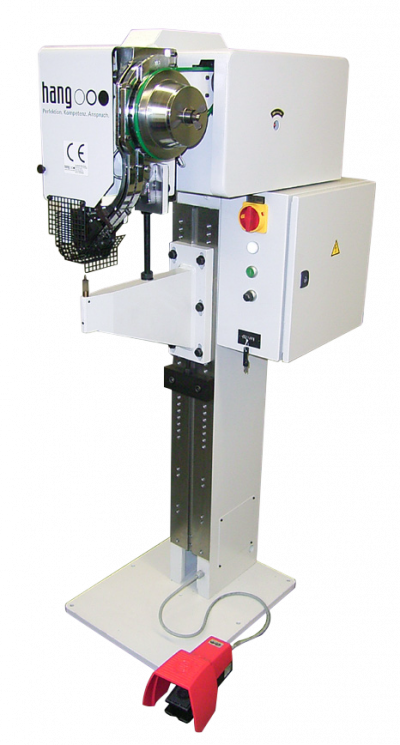

Riveting machine 162-22 with a wide range of applications

With the further models 162-01 and 162-21

Suitable for processing semi-tubular rivets, solid rivets, hollow rivets, tubular rivets, two-point rivets, double-tubular rivets (feed of the rivet cap), riveting machine for medium to large series

Reinforced configuration, sturdy welded designRivet feed with motor-driven rotating sorting container

Very little effort required for swapping rivet types due to quick-change components

Rivet gripper

Riveting pressure controlled via height adjustment of the bottom die

Positioning of pre-drilled workpieces via sprung rivet pin in the lower tool

Positioning of un-drilled workpieces via stops or sighting device

Drive with braking motor

Riveting force 16 or optionally 22 kN, for higher riveting forces up to max. 40 kN we recommend our model 162-21

Working depth 350 mm, model 162-01 is suitable for projections up to 620 mm

Release optionally with frontal finger guard and foot switch, alternatively with aiming device and foot lever or with 2-handed control

More options

Technical Data

| Unit | 162-22 | 162-01 | 162-21 | |

|---|---|---|---|---|

| Working depth (projection) | mm | 350 | 620 | 350 |

| Cycle time | sec | 0,5 | 0,7 | 0,7 |

| Special voltage | optional | optional | optional | |

| Electric part counter | ||||

| Pressure compensation | optional | optional | optional | |

| Process monitoring | optional | optional | optional | |

| Release via foot switch, frontal protective cage | ||||

| Release via foot lever, with sighting device | optional | optional | optional | |

| Release via 2-handed switch | optional | optional | optional | |

| Level monitoring in the rivet feed | optional | optional | optional | |

| Rivet feed via electromagnetic sorting unit | optional | optional | optional | |

| Rivet stroke | mm | 55 | 55 | 100 |

| Rivet stroke extended | optional | optional | optional | |

| Reinforced flat arm | ||||

| Riveting anvil variants for customer-specific applications | optional | optional | optional | |

| Working height | mm | 1100 | 1100 | 1100 |

| Working height, optional | mm | 850 / 1300 | 850 / 1300 | 850 / 1300 |

| Special configuration for integration into production lines | optional | optional | optional | |

| Special configuration for customer-specific applications | optional | optional | optional | |

| Working depth | mm | 50 | 50 | 50 |

| Special configuration for integration into production lines | optional | optional | optional | |

| Rivet diameter (after inspection) | mm | 2 - 5 | 2 - 4 | 3 - 8 |

| Riveting force | kN | 16 bzw 22 | 10 | max. 40 |

| Cycle time | sec | 0.7 | 0,7 | 0,7 |

| Drive capacity | kW | 0,37 (Option 1,1) | 0,37 | 3 |

Use cases

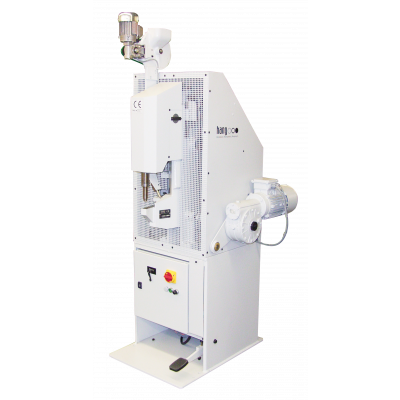

Similar machines