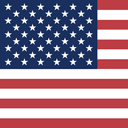

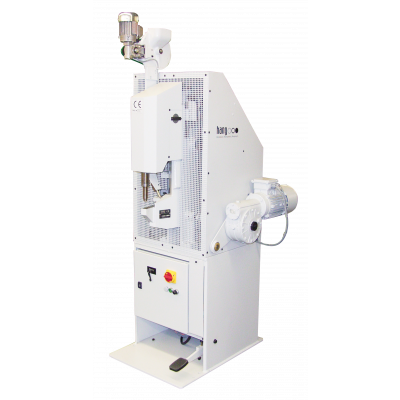

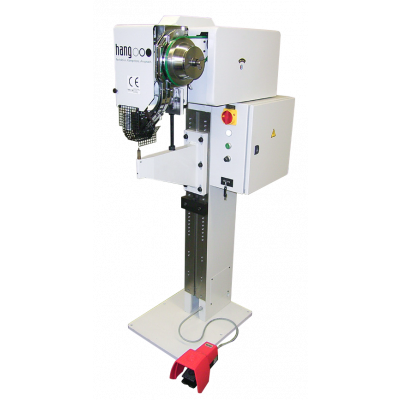

Riveting machine for high riveting forces of up to 40 kN

Suitable for working with semi-tubular, solid, hollow and tubular rivets - rivet shaft diameter 4 to 8 mm (per testing)

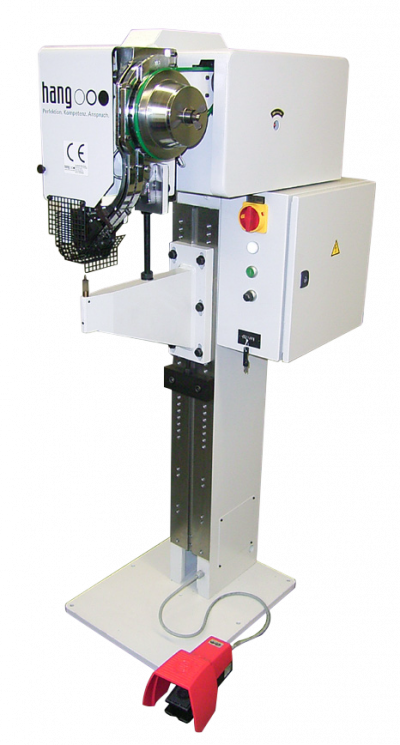

Riveting machine for medium to large series/batches

More options

Technical Data

| Unit | 162-21 | 162-01 | 162-22 / 162-21 / 162-01 | ||

|---|---|---|---|---|---|

| Working depth (projection) | mm | 350 | 620 | 350 | |

| Rivet cycle | sec | 1,1 | 0,5 | ||

| Special voltage | optional | optional | optional | ||

| Electric part counter | |||||

| Pressure compensation | optional | optional | optional | ||

| Process monitoring | optional | optional | optional | ||

| Release via foot switch, frontal protective cage | |||||

| Release via foot lever, with sighting device | optional | optional | optional | ||

| Release via 2-handed switch | optional | optional | optional | ||

| Level monitoring in the rivet feed | optional | optional | optional | ||

| Rivet feed via electromagnetic sorting unit | optional | optional | optional | ||

| Rivet stroke | mm | 100 | 55 | 55 | |

| Rivet stroke extended | optional | optional | optional | ||

| Reinforced flat arm | |||||

| Riveting anvil variants for customer-specific applications | optional | optional | optional | ||

| Collecting device for finished riveted parts | optional | ||||

| Working height | mm | 1100 | 1100 | 1100 | |

| Working height, optional | mm | 850 / 1300 | 850 / 1300 | 850 / 1300 | |

| Special configuration for integration into production lines | optional | optional | optional | optional | |

| Special configuration for customer-specific applications | optional | optional | optional | ||

| Rivet diameter (after inspection) | mm | 3 - 8 | 2 - 4 | 2 - 5 | |

| Riveting force | kN | max. 40 | 10 | 16 bzw 22 | |

| Cycle time | sec | 0,7 | 0,7 | 0,5 | 0.7 |

| Drive capacity | kW | 3 | 0,37 | 0,37 (Option 1,1) | |

| Working depth | mm | 50 | 50 | 50 |

Use cases

Similar machines