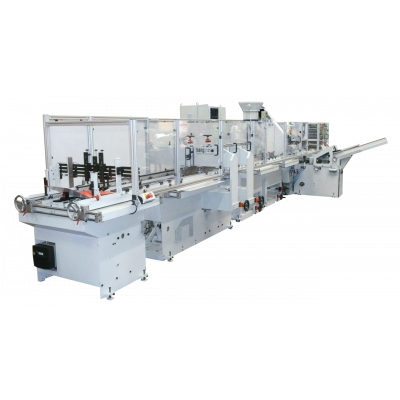

Combined lever arch and ring binder assembly line 470-00

With the fully automatic riveting machine of the 470 series, we present powerful combination solutions for the processing of lever arch and ring binder mechanisms. These systems stand out due to their innovative technical details, modular design and individual expansion options. An advantage of the 270/470 series is the dynamic, servo motor-driven cover positioning. It enables repeated exact positioning of the riveting elements (± 0.1 mm). Dimensional corrections can be easily programmed on the display. In addition to their impressive performance data, the robust, particularly user-friendly design is a convincing plus point. For users who want to produce even faster and more efficiently, the 470 is also available in a PLC version.

The following modules can be combined according to your individual requirements - up to a functional assembly line including modem for remote diagnosis.- Pre-stacking belt

- Board feeder

- Creasing station

- Punching and eyeletting station (grip hole eyelet)

- Punching and eyeletting station (slot eyelet)

- Riveting station (for processing ring and lever mechanisms)

- Pneumatic turning device

- Turning wheel

- Cover page station

- Automatic hold-down feeder

- Protective cardboard station

- Folding station High-performance double riveting machine with frequency-controlled brake motor drive.

- Automatic covering system from stacking magazine

- Independent cover transport via latch feed with servo drive

Rivet feeding via electromagnetic sorters

- For processing hollow rivets with 4 mm shaft diameter, length up to 19 mm, head diameter 6 - 8 or 8 - 10 mm

- Automatic separation and feeding of the ring mechanism by ratchet feed, pneumatic/mechanical - extremely reliable even at maximum speed

- Sensor controls at all filling levels (feeders, rivets, mechanisms, covers)

- Adjustment of rivet pitch with servo motor - pitch adjustable from 52 - 300 mm Additional advantages with PLC format adjustment:

- Extremely economical: even for batch sizes under 500

- Automatic format and mechanism adjustment: for max. 150 ring binder variants

- Program memory: stored data can be recalled at any time

Simple, fast programming: without prior knowledge, directly on the display, even when the machine is running

- Positioning/changeover at the push of a button: all axes within one minute, repeat accuracy 0.1 mm

Technical Data

| Unit | 470-00 | 600-00 | 270-00 | |

|---|---|---|---|---|

| Working height | mm | 900 | 900 | 900 |

| Material thickness | mm | 1,0 - 3,5 | 1,0 - 3,5 | 1,0 - 3,5 |

| Material thickness in special design | mm | 0,5 - 3,5 | 0,5 - 3,5 | 0,5 - 3,5 |

| Rivet pitch | mm | 52 - 300 | 52 - 300 | 82 - 300 |

| Crease offset | mm | 0 - 105 | 0 - 105 | 0 - 105 |

| Crease width | mm | 6 - 12 | 6 - 12 | 6 - 12 |

| Max. capacity | beats/min. | Material dependentring mechanism: 60lever mechanism: 50 | Material - dependent40 | Material dependent50 - 60 |

| Changeover time for changeover of all adjustable parameters | min. | Typ 470: ca. 30 - 45Typ 470 PLC: ca. 5 - 10 | Ca. 30 - 45 | Typ 270: ca. 10Typ 270 PLC: ca. 3 |

| Changeover time with changeover of individual adjustable parameters | correspondingly lower | correspondingly lower | - |

Use cases

Similar machines