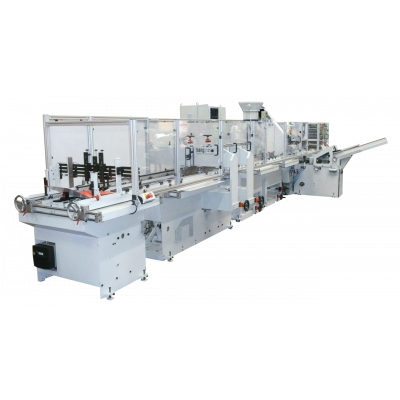

Ring binder assembly line 270-00

Here comes the generation of fully automatic riveting systems with an even larger format range. Ultra high production output due to increased cycle times and shorter set-up times. Particularly economical and safe due to wear-free drives, lower maintenance requirements, reliable mechanical feed and protective all-round cladding. Whether as a ring binder riveting system or as Type 470 in combination design for ring binders and folders, as a standard version or as a PLC version with optimised set-up times - all the arguments speak in favour of the new series.

The following modules can be combined according to your individual requirements - up to a functional assembly line including modem for remote diagnosis:

- Pre-stacking belt

- Board feeder

- Creasing station

- Punching and eyeletting station (grip hole eyelet)

- Riveting station

- Labelling station

- 3. Riveting station

- Pneumatic turning device

- Folding station High-performance double riveting machine with frequency-controlled brake motor drive

- Automatic covering system from stacking magazine

- Independent cover transport via latch feed with servo drive

- Rivet feeding via high capacity electromagnetic sorters

- For processing hollow rivets with 4 mm shaft diameter, length up to 19 mm,

head diameter 6 - 8 or 8 - 10 mm

- Automatic separation and feeding of the ring mechanism by ratchet feed,

pneumatic/mechanical - extremely reliable even at maximum speed

- Sensor controls at all filling levels (feeders, rivets, mechanisms, covers)

- Adjustment of rivet pitch with servo motor - pitch adjustable from 82 - 300 mm Additional advantages with PLC format adjustment:

- Extremely economical: even for batch sizes under 500

- Automatic format and mechanism adjustment: for max. 150 ring binder variants

- Program memory: stored data can be recalled at any time

- Simple, fast programming: without prior knowledge, directly on the display,

even when the machine is running

- Positioning/changeover at the push of a button: all axes within one minute,

repeat accuracy 0.1 mm

Technical Data

| Unit | 270-00 | 600-00 | 470-00 | |

|---|---|---|---|---|

| Working height | mm | 900 | 900 | 900 |

| Material thickness | mm | 1,0 - 3,5 | 1,0 - 3,5 | 1,0 - 3,5 |

| Material thickness in special design | mm | 0,5 - 3,5 | 0,5 - 3,5 | 0,5 - 3,5 |

| Rivet pitch | mm | 82 - 300 | 52 - 300 | 52 - 300 |

| Crease offset | mm | 0 - 105 | 0 - 105 | 0 - 105 |

| Crease width | mm | 6 - 12 | 6 - 12 | 6 - 12 |

| Max. capacity | beats/min. | Material dependent50 - 60 | Material - dependent40 | Material dependentring mechanism: 60lever mechanism: 50 |

| Changeover time for changeover of all adjustable parameters | min. | Typ 270: ca. 10Typ 270 PLC: ca. 3 | Ca. 30 - 45 | Typ 470: ca. 30 - 45Typ 470 PLC: ca. 5 - 10 |

| Changeover time with changeover of individual adjustable parameters | - | correspondingly lower | correspondingly lower |

Use cases

Similar machines